Protecting against environmental threats when shipping or storing your products can be a mixed bag. Understanding the types of conditions that threaten your products is key in deciding what materials — or combination of materials — will result in the level of protection you need to ensure safety and product functionality. Luckily, there are a few threats that you are more likely to encounter than others that can help you make the best packaging decision.

1 – Moisture

It is possible that if you are storing your product or equipment in a temperature-controlled indoor environment, you may not have moisture damage on your radar. But what happens when the HVAC unit needs repair or someone accidentally leaves the storage area door open longer than they should? Moisture issues can seep in through various means, inviting fungus issues like mold or mildew, even in climate-controlled facilities.

For example, it only takes 40% humidity to damage almost any product type. Yet most climate-controlled storage facilities consider 50% humidity as “optimal.” Even a small amount of moisture contamination can cause electronic devices to malfunction, machinery to rust, or any organic material to grow mold or other organisms.

Humidity is just one example of why controlling environmental threats is not as cut and dry as it may seem. Whether your asset is a military aircraft, part of a construction fleet, or the motherboard of a computer, moisture damage can render any of these items useless. Anticipating moisture control packaging needs on the front end is a sure way to increase cost savings.

2 – ESD

Moisture is often the first threat cited by companies shipping or storing electronic equipment. While moisture or humidity does adversely affect electronic devices, many people overlook another equally damaging hazard: electrostatic discharge (ESD).

Electrostatic discharge is when electricity flows between two objects. There are many causes of this, but in regards to shipping and storing of electrical equipment, even just carrying an electronic device across a carpeted floor can result in the discharge of electricity between the person carrying the item and the item itself. When this happens, if the voltage is great enough, the inner workings of the circuit board can be damaged, or even rendered unusable. It can often be difficult to immediately determine if any damage occurred as it may not be detectable until a later date.

As an often under-recognized threat, being aware of the potential for ESD damage is one way to ensure that your products are packaged safely.

3 – Logistics

Environmental contaminants are just one area of concern when it comes to transporting your high-value assets. Just as with a personal shipment, once your product leaves your hands, its treatment is out of your control. Damage can occur due to human error or because of unanticipated storage delays during transit. Adverse events like these are why transit requires an additional level of vigilance when preparing your products for shipment.

Scenarios like these mean you have to prepare for every possible contaminate that your package might encounter. Will it be shipped overseas on a cargo ship? Is there the possibility that your electronic equipment will come into contact with other products resulting in ESD-related damage? These threats spotlight the importance of proactively planning your packaging to protect against each of them.

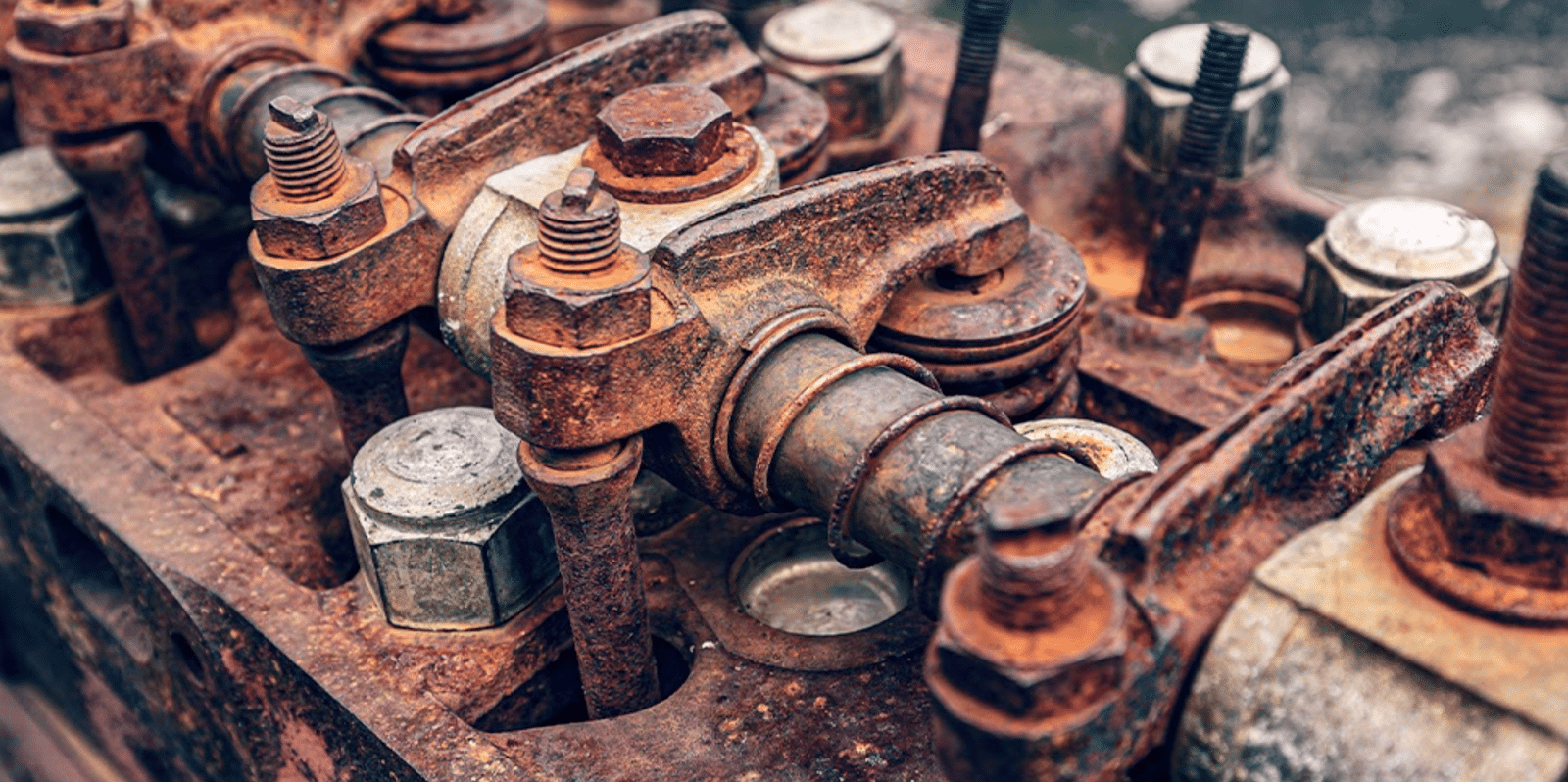

4 – Corrosion

Corrosion most often occurs with products or equipment made of metal, which is one of the most-often shipped materials. Understanding what causes corrosion and how it affects metal should inform your decisions surrounding the protective packaging that you choose.

Scientifically speaking, metal corrodes when it loses electrons to substances such as oxygen. When oxygen — or other corrosive substances — are able to take electrons from metal, the makeup of the metal changes, or oxidizes. Oxygen molecules cause a reaction that changes the constitution of the metal, making it brittle and weak.

At this point, the integrity of the entire product is at risk. At the very least, the lifespan of the product may be reduced. In the worst case, the equipment could fail to deploy in the field or a product malfunction could cause injury. Salt, dust, and other airborne contaminants…there are various instigators in the corrosion process, so knowing which you expect your asset to encounter will help to avoid metal corrosion.

Protect Against These Threats

Understanding the what, why, and how of environmental threats is the first step in being sure you are doing the best to protect your equipment. The next step is partnering with a proven, protective packaging provider to help you determine the most effective packaging materials to meet your storage and transit goals.

If you are looking for an innovative packaging solution, Protective Packaging Corporation is ready to engineer a solution to meet your industry needs. If you would like for us to do an onsite visit to provide suggestions or a quote, feel free to contact us online or call us at 1-866-229-0437.