MIL-PRF-22191 MATERIALS

| WE CARRY THE FOLLOWING MIL-PRF-22191 CLEAR BARRIER MATERIALS | ||||

| Material Name | Brand/MFG | Mil Spec | Data Sheet |  |

| Protect 2000 | Ultra 2000 | Mil-PRF-22191 Type I | ||

| Protect 5500 | FR 5500 | Mil-PRF-22191 Type II | ||

MIL-PRF-22191 Performance Specification

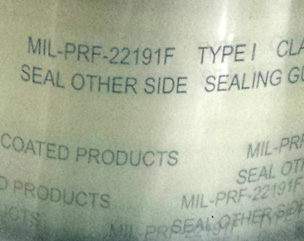

(THIS IS AN EXCERPT OF MIL-PRF-22191 PERFORMANCE SPECIFICATIONS AS PROVIDED BY THE US GOVERNMENT. FOR THE COMPLETE AND CURRENT DOCUMENT, VISIT THE US DEPARTMENT OF DEFENSE ASSIST.DLA.MIL) INCH-POUND MIL-PRF-22191F w/AMENDMENT 1 26 October 2009 SUPERSEDING MIL-PRF-22191F 31 March 2008 PERFORMANCE SPECIFICATION BARRIER MATERIALS, TRANSPARENT, FLEXIBLE, HEAT-SEALABLE This specification is approved for use by all Departments and Agencies of the Department of Defense. 1. SCOPE Scope. This specification establishes the requirements for transparent, flexible, heatsealable barrier materials having waterproof or low water vapor transmission characteristics for use in military packaging. 2. REQUIREMENTS Qualification – The barrier materials furnished under this specification shall be products that are authorized by the qualifying activity for listing on the applicable qualified products list before contract award. Material – Barrier materials shall be made from such materials and by such processes as to ensure compliance with the performance requirements of this specification. Construction – Barrier materials shall be constructed of one or more plies in any manner which ensures compliance with the performance requirements of this specification. Butting of component materials or the finished product shall not be permitted except in the direction perpendicular to the rolling direction. When a butt weld is made on the finished product or any ply thereof, the areas shall be externally flagged with colored markers to prevent use of that portion of the roll. – Splices. A roll shall not contain more than 3 splices (4 pieces) and each piece shall be not less than 45 yards in length. Splices within rolls shall be even the entire width of the roll material and shall not come apart during unwinding of the roll. Rolls containing splices shall be flagged at both ends of each splice with colored markers to indicate splices within the roll. Barrier material in flat cut sheets shall not contain splices. Form – The barrier material shall be furnished in rolls or flat cut sheets as specified in the contract or delivery order. – Rolls. The width of roll material shall be 36 inches, with a tolerance of plus ¼ inch or minus 1/8 inch. The average length of any roll material shall be not less than 200 yards. The length of any individual roll shall be not less than 195 yards. The roll material shall be uniformly wound on nonreturnable cores. The inside diameter of the core shall be not less than 3 inches with a tolerance of plus 1/8 inch. The length of the core shall be equal to the width of the roll material, with a tolerance of plus 1/8 inch. The core shall be rigid to prevent distortion of the roll during use and shipment conditions. Each roll shall be restrained to prevent unwinding. – Sheets. When flat cut sheets are specified, the length and width shall be as specified by the acquiring activity. If the length and width tolerances for cut sheets are not specified, the tolerance for each shall be plus ¼ inch or minus 1/8 inch. Flat cut sheets shall be evenly stacked. Sealing – Barrier materials shall be heat sealed under conditions recommended by manufacturer. These sealing conditions shall be conditions that are considered reasonable for production line sealing operations with respect to commonly available sealing equipment and commercially practical fabrication time. The barrier material identification of material markings shall include the sealing conditions. The material shall exhibit no delamination at the heat-sealed area when sealed under the manufacturer’s recommended conditions. Each roll or package (flat cuts) of barrier material shall include a tag secured to the core of rolls, or sheet inserted in the package of sheets with the sealing instructions for heat-sealing on rotary, band, and jaw-type sealing equipment. The tag or sheet shall be visible upon opening the unit package. Identification of material – The specification number, type, class, manufacturer’s name, manufacturer’s designation, month and year of manufacture, lot number, heat-sealing conditions (temperature, pressure and dwell time) and the notation “Seal other Side” if applicable shall be clearly and legibly marked using water-resistant ink on the non-sealable side of the barrier material. The color of the markings shall be blue. The complete markings shall be continuous lengthwise and the distance between groups of markings shall be not greater than 2 inches. A complete group of markings shall appear once in each 2½ inches of width of the roll. The letters and figures shall be not less than 1/8 of an inch high. Performance requirements – The performance of the barrier materials shall conform to the requirements specified in table I, when tested in accordance with 4.6. Workmanship – Barrier material surfaces shall be free from any foreign matter. The barrier material edges shall be cut and trimmed of any selvage. Barrier material shall be free from holes, tears, cuts, sharp creases, wrinkles, or other imperfections.TABLE I. Performance requirements.

|

Characteristics |

Types I, II, III Requirements |

| Thickness (inches)(max) | 0.0060 |

| Seam Strength 1. As received material sealed & tested: a. At room temperature (separation-inches) b. At 100°F and at 160°F (separation-inches) 2. Sealed before aging at 160°F for 12 days and tested: a. At room temperature (separation-inches) b. At 100°F and at 160°F (separation-inches) 3. Sealed after aging at 160°F for 12 days and tested: a. At room temperature (separation-inches) b. At 100°F and at 160°F (separation-inches) | No separation No separationNo separation No separation No separation No separation |

| Seam Fabrication | No leaks at any seams |

| Water vapor transmission rate (WVTR) (Type I only) 1. After room temperature flexing: a. As received (gms/100 sq. in./24 hrs.)(max) b. Aged (gms/100 sq. in./24 hrs.)(max) 2. WVTR after low temperature flexing: As received (gms/100 sq. in./24 hrs.)(max) | 0.02 (max) 0.02 (max)0.03 (max) |

| Water vapor transmission rate (WVTR) (Modulated Infrared Sensor) (Type I only) As received (gms/100 sq. in./24 hrs)(max) | 0.02 |

| Transparency a. As received b. After aging 12 days at 160 °F | Read lettering 3 inches behind material |

| Puncture resistance a. Type I (lbs, (min) b. Type II (lbs, (min) c. Type III (lbs, (min) | 10 8.0 6.0 |

| Blocking resistance | No blocking delamination or rupture |

| Resistance to curl (Class 1 only) | Shall not curl in excess of 5 % or back upon itself |

| Contact corrosivity | No corrosion, etching or pitting |

| Oil resistance (delamination) multi-ply materials only | No leakage, swelling, delamination, or embrittlement |

| Waterproofness (Type II and Type III only) | No dye penetration |

| Aging resistance (Multi-ply materials only) | No delamination |

| Water resistance of marking | Markings are clear and legible |

| Marking abrasion resistance | Shall be legible |

| One year storage stability: 1. Seam strength a. As received material sealed & tested at room temperature (seal separation) b. Sealed after aging at 160 °F for 12 days and tested at room temperature (seal separation)2. Oil resistance (delamination). Multi-ply material only 3. Transparency 4. Water vapor proof transmission rate after room temperature flexing a. as received (gms/100 sq. in./24 hours)(max) b. Aged (gms/100 sq. in./24 hours) (max) | No separation No separation No leakage, swelling, delamination, or embrittlement Read lettering 3 inches behind material 0.02 0.02 |