MIL-PRF-22191 is the U.S. military specification for transparent, flexible, heat-sealable barrier materials with low water-vapor transmission. These materials are essential for packaging and preserving sensitive equipment in demanding environments where moisture, salt spray, and rough handling can cause corrosion or degradation.

At Protective Packaging, we supply MIL-PRF-22191 certified materials in multiple formats, with the ability to convert rolls into bags, tubing, or sheets. Our solutions are trusted by defense, aerospace, naval aviation, and industrial clients who need uncompromising barrier performance.

MIL-PRF-22191 MATERIALS

| WE CARRY THE FOLLOWING MIL-PRF-22191 CLEAR BARRIER MATERIALS | ||||

| Material Name | Brand/MFG | Mil Spec | Data Sheet |  |

| Protect 2000 | Ultra 2000 | Mil-PRF-22191 Type I | ||

| Protect 5500 | FR 5500 | Mil-PRF-22191 Type II | ||

All materials are available as bags, tubing, sheets and rolls.

MIL-PRF-22191 Performance Specification

(This is an excerpt of MIL-PRF-22191 performance specifications as provided by the U.S. Government. For the complete and current document, visit the U.S. Department of Defense at assist.dla.mil.)

INCH-POUND

MIL-PRF-22191F w/AMENDMENT 1 — 26 October 2009

Superseding MIL-PRF-22191F — 31 March 2008

(Performance Specification: Barrier Materials, Transparent, Flexible, Heat-Sealable)

This specification is approved for use by all Departments and Agencies of the Department of Defense.

Scope

This specification establishes the requirements for transparent, flexible, heat-sealable barrier materials having waterproof or low water vapor transmission characteristics for use in military packaging.

MIL-PRF-22191 Requirements

Qualification

Barrier materials furnished under this specification shall be products authorized by the qualifying activity for listing on the applicable Qualified Products List before contract award.

Material

Barrier materials shall be manufactured from such materials and by such processes as to ensure compliance with the performance requirements of this specification.

Construction

Barrier materials shall be constructed of one or more plies in any manner that ensures compliance with performance requirements.

- Butting of component materials or finished product is not permitted except in the direction perpendicular to the rolling direction.

- When a butt weld is made on the finished product or any ply, the areas shall be externally flagged with colored markers to prevent use of that portion of the roll.

Splices

- A roll shall not contain more than 3 splices (4 pieces), and each piece shall be no less than 45 yards in length.

- Splices within rolls shall extend across the entire width and shall not come apart during unwinding.

- Rolls containing splices shall be flagged at both ends of each splice with colored markers.

- Flat cut sheets shall not contain splices.

Form

Barrier material shall be furnished in rolls or flat cut sheets as specified in the contract or delivery order.

Rolls

- Standard width: 36 inches (tolerance: +¼ inch / -⅛ inch).

- Average roll length: not less than 200 yards.

- Individual roll length: not less than 195 yards.

- Cores: nonreturnable, rigid, 3-inch inside diameter (±⅛ inch), length equal to roll width (±⅛ inch).

- Rolls shall be uniformly wound and restrained to prevent unwinding.

Sheets

- Length and width as specified by acquiring activity.

- Default tolerances: +¼ inch / -⅛ inch.

- Sheets must be evenly stacked.

Sealing

Barrier materials shall be heat sealed under conditions recommended by the manufacturer.

- Sealing conditions must be reasonable for production line operations with standard equipment.

- Materials shall exhibit no delamination at sealed areas.

- Each roll or package must include a tag or sheet listing sealing instructions for rotary, band, and jaw-type sealers.

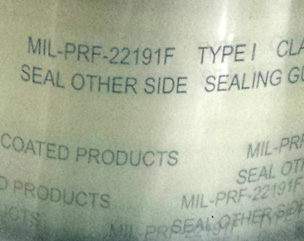

Identification of Material

The following must be legibly marked using blue, water-resistant ink on the non-sealable side:

- Specification number, type, class

- Manufacturer’s name and designation

- Month/year of manufacture

- Lot number

- Heat-sealing conditions (temperature, pressure, dwell time)

- Notation “Seal Other Side” (if applicable)

Markings shall:

- Be continuous lengthwise

- Appear once every 2½ inches across roll width

- Have letters/numbers no smaller than ⅛ inch

Performance Requirements

Barrier materials shall conform to the requirements listed in Table I, when tested in accordance with section 4.6.

Workmanship

Barrier material surfaces must be free from foreign matter. Edges shall be cleanly trimmed of selvage. Materials must be free from:

- Holes, tears, or cuts

- Sharp creases or wrinkles

- Any other imperfections

TABLE I. Performance requirements.

Characteristics | Types I, II, III Requirements |

| Thickness (inches)(max) | 0.0060 |

| Seam Strength 1. As received material sealed & tested: a. At room temperature (separation-inches) b. At 100°F and at 160°F (separation-inches) 2. Sealed before aging at 160°F for 12 days and tested: a. At room temperature (separation-inches) b. At 100°F and at 160°F (separation-inches) 3. Sealed after aging at 160°F for 12 days and tested: a. At room temperature (separation-inches) b. At 100°F and at 160°F (separation-inches) | No separation No separation |

| Seam Fabrication | No leaks at any seams |

| Water vapor transmission rate (WVTR) (Type I only) 1. After room temperature flexing: a. As received (gms/100 sq. in./24 hrs.)(max) b. Aged (gms/100 sq. in./24 hrs.)(max) 2. WVTR after low temperature flexing: As received (gms/100 sq. in./24 hrs.)(max) | 0.02 (max) 0.02 (max)0.03 (max) |

| Water vapor transmission rate (WVTR) (Modulated Infrared Sensor) (Type I only) As received (gms/100 sq. in./24 hrs)(max) | 0.02 |

| Transparency a. As received b. After aging 12 days at 160 °F | Read lettering 3 inches behind material |

| Puncture resistance a. Type I (lbs, (min) b. Type II (lbs, (min) c. Type III (lbs, (min) | 10 8.0 6.0 |

| Blocking resistance | No blocking delamination or rupture |

| Resistance to curl (Class 1 only) | Shall not curl in excess of 5 % or back upon itself |

| Contact corrosivity | No corrosion, etching or pitting |

| Oil resistance (delamination) multi-ply materials only | No leakage, swelling, delamination, or embrittlement |

| Waterproofness (Type II and Type III only) | No dye penetration |

| Aging resistance (Multi-ply materials only) | No delamination |

| Water resistance of marking | Markings are clear and legible |

| Marking abrasion resistance | Shall be legible |

One year storage stability: 3. Transparency 4. Water vapor proof transmission rate after room temperature flexing | No separation No separation No leakage, swelling, delamination, or embrittlement Read lettering 3 inches behind material 0.02 |

MIL-PRF-22191 Notes

(This section contains information of a general or explanatory nature that may be helpful but is not mandatory.)

Intended Use

MIL-PRF-22191 barrier materials are designed for specialized military preservation methods. Their performance characteristics—water vapor transmission rate, transparency, contact corrosivity, storage stability, seam strength, puncture resistance, blocking and curl resistance, delamination, and waterproofness—provide protection under extreme naval/aviation conditions.

Navy and naval aviation items often face:

- High moisture and salt exposure

- Transfers at sea

- Rough handling

- Minimal storage conditions

No commercial equivalents meet these requirements for protecting materiel in operational naval aviation environments.

MIL-STD-2073-1 Methods

Specifically, Methods of Preservation 31, 32, 33, 41, and 51 of MIL-STD-2073-1 call for MIL-PRF-22191 as the premier source of transparent, waterproof, and watervaporproof (including with desiccant) protection.

Role in Preservation

MIL-PRF-22191 serves as a foundation for specialized military preservation techniques approved under MIL-STD-2073-1.

Applications & Use Cases

MIL-PRF-22191 barrier materials are intended for specialized military preservation methods and have no commercial equivalents that meet the same physical, mechanical, and corrosion-resistant standards. Typical use cases include:

- Long-term storage of aerospace and defense parts.

- Naval aviation equipment subject to high humidity and salt spray.

- Electronics and avionics requiring clear moisture protection.

- Industrial machinery components stored or shipped overseas.

- Packaging requiring transparent, watervaporproof, and greaseproof protection.

These materials are referenced in MIL-STD-2073-1 methods 31, 32, 33, 41, and 51, which outline approved military preservation techniques.

Ordering & Customization

Barrier materials are supplied in standard rolls or flat sheets but can be customized to meet specific requirements.

- Available as rolls, sheets, tubing, or custom-sized bags.

- Rolls can be converted into other formats on request.

- Bulk pricing and freight shipping available by phone.

To request a quote or discuss custom conversions, call us at 1-888-972-7157 or use our online contact form.

FAQs

What does MIL-PRF-22191 cover?

It defines transparent, flexible, heat-sealable barrier materials that are waterproof or watervaporproof. These are used for military packaging to prevent corrosion and environmental damage.

What are the differences between Types I, II, and III?

Each type varies slightly in puncture resistance, waterproofness, and construction. All meet core performance specs but are chosen based on packaging needs and storage conditions.

Can these materials be ordered as bags or tubing?

Yes. While standard rolls are available, we can convert materials into custom bags, tubing, or flat sheets.

How should I seal this material?

Use manufacturer-recommended heat-sealing conditions. Materials should exhibit no delamination when sealed properly, ensuring long-term performance.

Are there commercial equivalents?

No. The spec was created for military packaging and provides a level of performance that commercial materials do not match.

Trusted MIL-PRF-22191 Protection You Can Rely On

When it comes to meeting MIL-PRF-22191 performance specifications, there’s no room for compromise. Protective Packaging delivers barrier materials that meet or exceed all military standards while giving you the flexibility to order in rolls, sheets, tubing, or custom-sized bags. Whether you’re storing aerospace components, naval aviation equipment, or sensitive electronics, our team ensures your assets remain fully protected against moisture, corrosion, and environmental extremes.

Call us today at 1-888-972-7157 or request a quote online to discuss your requirements and secure certified MIL-PRF-22191 materials tailored to your needs.