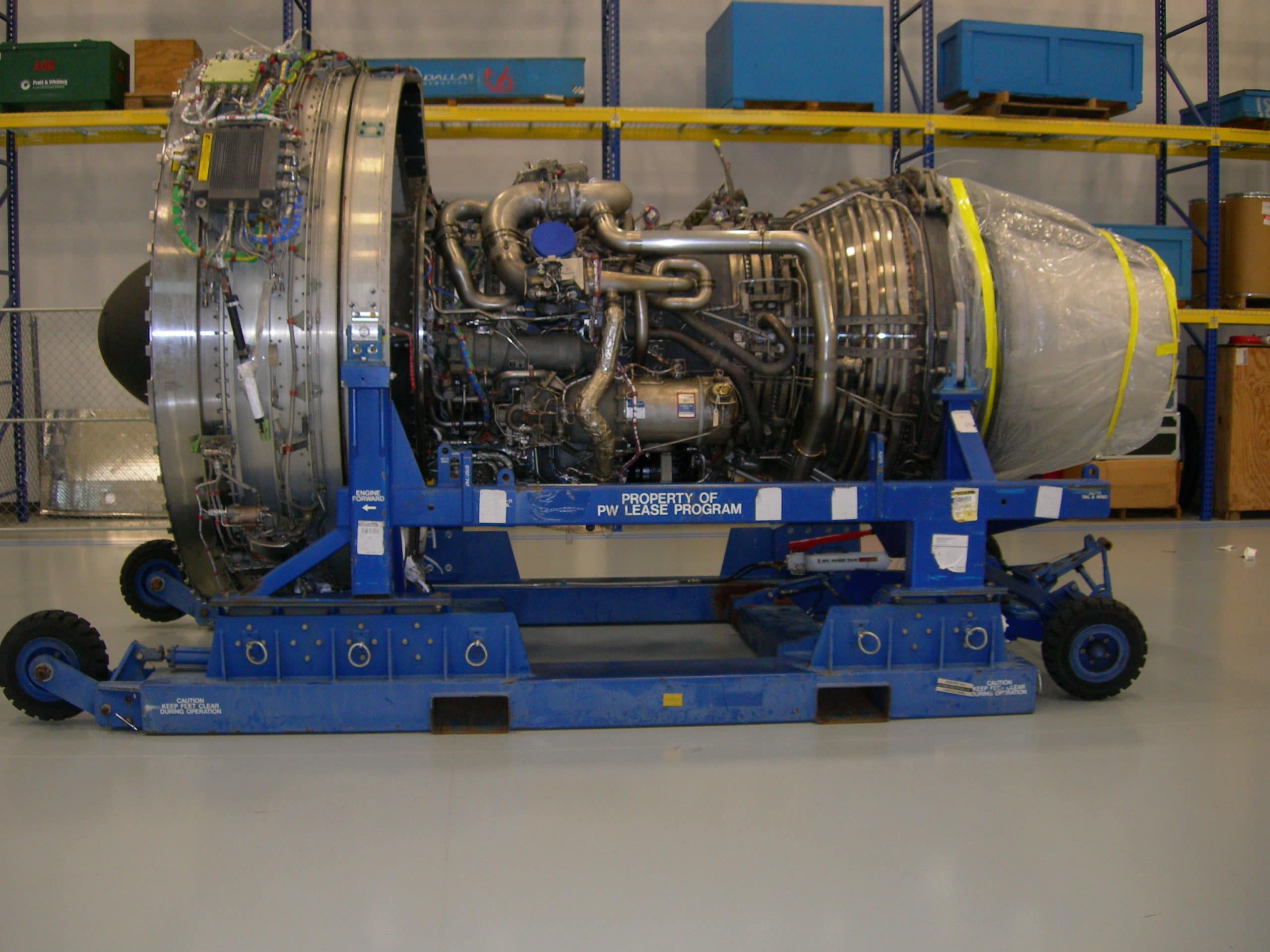

Large commercial engines were being stored outside, wrapped with stretch film. The engines developed corrosion and had to be completely overhauled.

Corrosion is a plight faced by everyone who works with metals. Its impact on the US economy has been documented at about 4% of the gross national product. It has also been estimated that about one third of the corrosion damage could be avoided. Such was the challenge in the case of large commercial engines. The resulting solution needed to be a combination of custom fitting, strong, and durable materials combined with Volatile Corrosion Inhibitors (VCI’s).

A custom made barrier bag was designed to fit over the engine but also fit inside the cradle holding the engine. The corrosion was totally eliminated, resulting in an annual savings in labor costs alone of $250,000.